Exploring the Types of Multilayer Boards Available in Electronics

2024-05-24

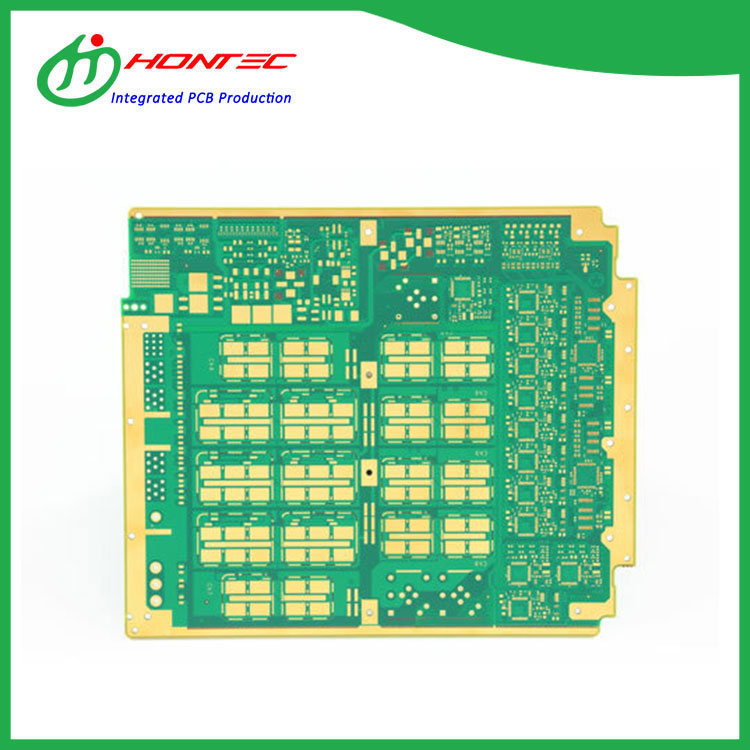

In the realm of electronics, multilayer boards play a crucial role in enabling complex circuitry and functionality in various devices. But did you know that there are different types of multilayer boards, each with its unique characteristics and applications? Let's dive into the world of multilayer boards and explore the various types available.

1. Standard Multilayer Boards

Standard multilayer boards are the most common type and consist of alternating layers of conductive (copper) and non-conductive (dielectric) materials. They are typically used in applications that require moderate complexity and density, such as consumer electronics and computing devices. Standard multilayer boards offer a cost-effective solution for many applications, while still providing the necessary functionality.

2. High-Density Interconnect (HDI) Boards

HDI boards are designed for high-density applications that require a large number of interconnections between layers. They feature microvias, which are small vias that allow for increased connectivity and reduced board size. HDI boards are commonly used in smartphones, tablets, and other mobile devices, where space is limited and the need for high-density circuitry is crucial.

Flexible multilayer boards, also known as flex-rigid boards, combine the flexibility of flexible PCBs with the rigidity and stability of traditional multilayer boards. They consist of both flexible and rigid layers, allowing for the design of curved or irregularly shaped boards. Flexible multilayer boards are often used in applications where space is limited or where the board needs to conform to a specific shape, such as in wearable devices and medical implants.

4. Metal Core Boards

Metal core boards are multilayer boards that use a metal substrate, such as aluminum, instead of the traditional non-conductive substrate. The metal core provides excellent heat dissipation, making metal core boards ideal for high-power applications that require efficient heat management. They are commonly used in power supplies, LED lighting, and other applications where heat generation is a concern.

5. Mixed-Dielectric Boards

Mixed-dielectric boards utilize different types of dielectric materials in their construction. This allows for more flexibility in design and can optimize certain properties, such as electrical performance, heat dissipation, or mechanical strength. Mixed-dielectric boards are often used in specialized applications where specific requirements need to be met.

Conclusion

As you can see, there is a wide variety of multilayer boards available, each with its unique characteristics and applications. From standard multilayer boards to specialized types like HDI boards, flexible multilayer boards, metal core boards, and mixed-dielectric boards, the choice of multilayer board depends on the specific requirements of the application. Understanding the different types of multilayer boards and their capabilities can help you make an informed decision when designing your next electronic device.