How to Choose the Right Sheet Metal V Grooving Machine for Your Needs

2024-10-29

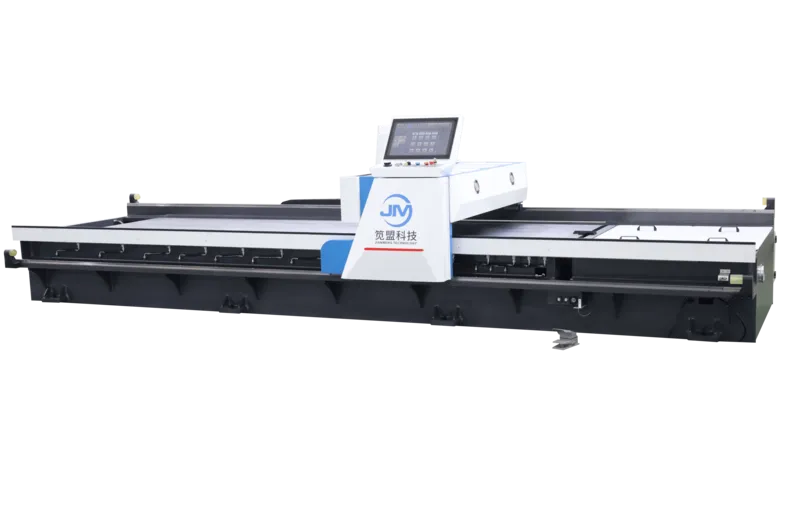

When it comes to metal fabrication, selecting the right tools is vital for efficiency and quality. A sheet metal V grooving machine is a key asset for achieving precise bends and reducing material waste. However, with various models and features available, how do you choose the right one for your needs? In this blog, we’ll discuss important factors to consider when selecting a sheet metal V grooving machine.

1. Material Compatibility

One of the first considerations should be the type of materials you plan to work with. Ensure the machine can handle the thickness and type of sheet metal required for your projects. Some machines are better suited for aluminum, while others may be optimized for steel or other materials.

2. Grooving Depth and Angle

Different projects require different grooving depths and angles. When choosing a V grooving machine, check its specifications for adjustable cutting depths and angles. This flexibility allows you to adapt the machine for various applications and ensures it can meet your specific requirements.

3. Machine Size and Footprint

Consider the size of the machine and the available space in your workshop. A compact machine may be more suitable for smaller workshops, while larger models may be needed for high-volume production. Ensure that you have enough space for the machine as well as for loading and unloading materials safely.

4. Ease of Use and Setup

Look for machines that offer user-friendly controls and easy setup processes. A straightforward interface can significantly reduce training time for operators and increase overall productivity. Additionally, consider features like automatic depth adjustment or digital readouts, which can enhance precision and ease of operation.

5. Power Source

Sheet metal V grooving machines can be powered by hydraulic, pneumatic, or mechanical systems. Each power source has its advantages and disadvantages, so consider what best suits your operational needs. Hydraulic machines are often favored for their power and precision, while mechanical models may offer simplicity and ease of maintenance.

6. Maintenance and Support

Regular maintenance is crucial for ensuring the longevity and performance of your V grooving machine. When evaluating options, check the manufacturer’s reputation for customer support and the availability of replacement parts. A solid warranty and good service can save you time and money in the long run.

7. Budget Considerations

Finally, factor in your budget. While it may be tempting to go for the cheapest option, consider the long-term value of the machine. Investing in a higher-quality machine may yield better performance, durability, and efficiency, ultimately saving you money on repairs and replacements.

Choosing the right sheet metal V grooving machine involves careful consideration of various factors, including material compatibility, grooving specifications, machine size, ease of use, power source, maintenance, and budget. By taking the time to evaluate these aspects, you can invest in a machine that meets your needs and enhances your metal fabrication capabilities. A well-chosen V grooving machine will not only improve efficiency but also elevate the quality of your finished products, making it a valuable asset in your workshop.