NBR Rubber Compound: A Durable Solution for Challenging Applications

2025-01-20

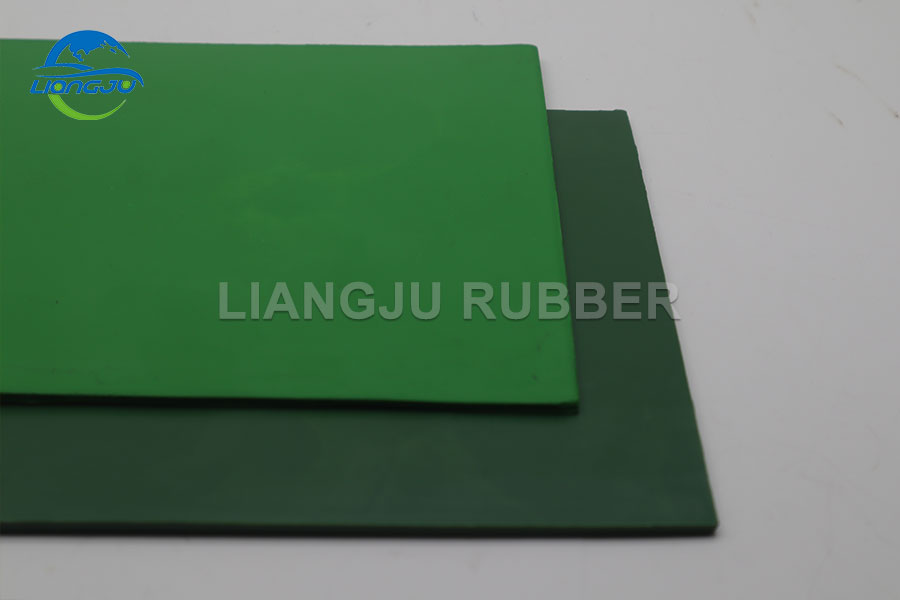

In the world of industrial and automotive components, the materials used play a crucial role in the performance, longevity, and reliability of products. One such material that has gained significant attention for its versatility and resilience is NBR rubber compound. Also known as Nitrile Butadiene Rubber (NBR), this synthetic rubber compound is engineered to provide excellent resistance to oil, fuel, and other challenging substances, making it ideal for a wide range of applications.

What is NBR Rubber Compound?

NBR Rubber Compound is a synthetic rubber made by polymerizing butadiene and acrylonitrile. The unique chemical structure of NBR provides it with a set of remarkable properties, particularly its resistance to oils, fuels, solvents, and other chemicals. The acrylonitrile content in the polymer determines the compound’s resistance to petroleum-based oils, while the butadiene component gives it flexibility and resilience.

NBR rubber is available in a variety of grades, each tailored to meet specific industry needs. The compound can be further modified with different additives to improve properties such as heat resistance, abrasion resistance, and tensile strength.

Key Properties of NBR Rubber Compound

1. Oil and Fuel Resistance

One of the standout features of NBR rubber is its exceptional resistance to oils, fuels, and greases. This makes it an ideal material for products exposed to petroleum-based substances. The compound's high resistance to hydrocarbons makes it particularly popular in the automotive and industrial sectors, where parts are frequently exposed to oils and lubricants.

2. Excellent Abrasion Resistance

NBR rubber has excellent resistance to abrasion, which is crucial for applications that involve frequent wear and tear. This durability ensures that components such as seals, gaskets, and hoses last longer, even in harsh environments.

3. Low Compression Set

The compression set of a material refers to its ability to return to its original shape after being compressed. NBR rubber demonstrates a low compression set, meaning it retains its shape and functionality after being subjected to pressure. This is especially important for sealing applications, where maintaining a tight seal is essential for performance.

4. Good Flexibility and Elasticity

Despite its toughness, NBR rubber retains its flexibility and elasticity, even at low temperatures. This property makes it ideal for sealing applications that require a material that can bend or stretch without cracking or losing its effectiveness.

5. Resistance to Temperature Extremes

NBR rubber can operate effectively in a range of temperatures, typically between -40°C to +120°C (-40°F to +248°F), depending on the formulation. This makes it suitable for a variety of environments, including those that experience both high and low temperatures.

6. Chemical Resistance

Apart from oils and fuels, NBR rubber also demonstrates resistance to a variety of chemicals and solvents, making it a go-to material for products exposed to harsh chemicals in industries like oil and gas, automotive, and manufacturing.

Common Applications of NBR Rubber Compound

The versatility of NBR rubber compound makes it suitable for a wide range of applications across different industries. Some of the most common uses include:

1. Automotive Industry

In the automotive sector, NBR rubber is used extensively for seals, gaskets, fuel hoses, O-rings, and vibration dampers. Its ability to withstand exposure to oils, fuels, and high temperatures makes it a preferred choice for automotive components that require durability and reliability.

- Fuel System Components: NBR rubber is commonly used for gaskets, seals, and fuel hoses in cars and trucks.

- Transmission Seals: Due to its ability to resist high temperatures and oils, NBR rubber is often used in transmission seals and other critical automotive components.

2. Oil and Gas Industry

The oil and gas industry frequently deals with harsh environments that involve exposure to petroleum-based products, extreme temperatures, and abrasive materials. NBR rubber is ideal for seals, gaskets, and hoses used in pipelines, pumps, and valves.

- Seal Rings: NBR is widely used for rotary seals, static seals, and piston seals in oil and gas equipment.

- Downhole Tools: NBR rubber compounds are used in tools and machinery that are exposed to extreme conditions in drilling and extraction processes.

3. Manufacturing and Industrial Applications

In industrial machinery, NBR rubber is used for a variety of components such as gaskets, vibration dampers, and O-rings. Its resistance to oils, fuels, and other chemicals makes it an excellent choice for manufacturing plants that handle lubricants, chemicals, and solvents.

- Conveyor Belts: NBR is used in the production of durable, abrasion-resistant conveyor belts that come into contact with oils or chemicals.

- Gaskets and Seals: In machinery and equipment, NBR rubber is commonly used for sealing joints and preventing leaks.

4. Food Processing Industry

While NBR rubber is not suitable for direct contact with food, it is often used in food processing equipment that requires resistance to oils, greases, and cleaning agents. NBR rubber seals and gaskets ensure that food processing machines operate efficiently while preventing contamination.

5. Medical Equipment

Certain formulations of NBR are used in medical equipment like surgical gloves, gaskets, and seals that require oil resistance, flexibility, and strength. However, NBR is not as widely used in the medical field as natural rubber or silicone due to its potential to cause allergic reactions.

NBR rubber compound is a robust, reliable, and cost-effective material that plays a crucial role in a wide variety of industries. From automotive parts to industrial seals and gaskets, its unique properties—such as oil resistance, flexibility, and durability—make it an excellent choice for demanding applications. By understanding its characteristics and benefits, manufacturers can make informed decisions when selecting materials for their products, ensuring both performance and longevity in challenging environments. Whether you're designing automotive components, industrial machinery, or oil and gas equipment, NBR rubber is a versatile solution that combines strength with flexibility, providing long-lasting protection and reliability.