Unveiling Petroleum Resin: Production, Properties, and Applications

2024-03-18

Petroleum resin, a versatile and widely used synthetic resin, plays a pivotal role in various industries, ranging from adhesives and coatings to printing inks and rubber compounds. In this blog, we'll delve into what petroleum resin is, how it's produced, and its diverse applications across different sectors.

Understanding Petroleum Resin:

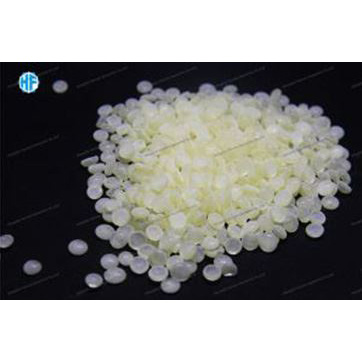

Petroleum resin is a type of synthetic resin derived from petroleum feedstocks through a complex polymerization process. It falls under the category of thermoplastic resins, which means it can soften and flow when heated and solidify upon cooling. Petroleum resin exhibits a wide range of properties, including excellent adhesion, compatibility with other materials, and resistance to heat and chemicals, making it a valuable ingredient in various industrial applications.

Production Process:

The production of petroleum resin typically involves the following steps:

1. Feedstock Selection: The process begins with the selection of suitable petroleum feedstocks, which may include various fractions derived from crude oil refining, such as heavy naphtha or refinery gases.

2. Polymerization: The selected feedstocks undergo a polymerization process, where the molecules are chemically bonded together to form larger polymer chains. This polymerization can be achieved through various methods, including thermal or catalytic processes.

3. Fractionation and Distillation: After polymerization, the resulting polymer mixture is fractionated and distilled to separate the desired petroleum resin fractions based on their molecular weight, composition, and properties.

4. Modification and Blending: In some cases, petroleum resin may undergo further modification or blending with other additives to tailor its properties for specific applications. This may include adjusting the molecular weight, softening point, or tackiness of the resin.

5. Packaging and Distribution: The final petroleum resin products are packaged and distributed to customers across various industries, where they are incorporated into formulations for adhesives, coatings, inks, and other products.

Properties and Characteristics:

Petroleum resin exhibits a diverse range of properties that make it highly versatile and suitable for a wide range of applications:

- Adhesion: Petroleum resin provides excellent adhesion properties, making it ideal for use in adhesives and sealants formulations.

- Compatibility: It is compatible with a variety of materials, including polymers, solvents, and additives, allowing for easy formulation adjustments.

- Heat Resistance: Petroleum resin exhibits high heat resistance, making it suitable for applications requiring elevated temperature stability, such as hot-melt adhesives and coatings.

- Color and Clarity: Depending on the production process and formulation, petroleum resin can range in color from pale yellow to amber and exhibit excellent clarity in finished products.

Applications:

Petroleum resin finds extensive use in a wide range of industries and applications, including:

- Adhesives and Sealants: It serves as a key ingredient in formulating adhesives and sealants for bonding various substrates in construction, automotive, and packaging applications.

- Coatings and Paints: Petroleum resin enhances the performance of coatings and paints by improving adhesion, gloss, and durability while providing resistance to weathering and chemicals.

- Inks and Printing: It is used in the formulation of printing inks for flexographic, gravure, and screen printing applications, offering fast drying times, excellent color dispersion, and adhesion to various substrates.

- Rubber Compounding: Petroleum resin improves the processing characteristics and performance of rubber compounds, such as tires, by enhancing tackiness, reinforcement, and adhesion to substrates.

Conclusion:

Petroleum resin is a versatile and indispensable synthetic resin that plays a vital role in numerous industrial applications. Its unique properties, including adhesion, compatibility, and heat resistance, make it a preferred choice for formulators seeking to enhance the performance and durability of their products. By understanding the production process and properties of petroleum resin, manufacturers and end-users can harness its versatility to create innovative solutions across diverse sectors, driving progress and efficiency in the modern industrial landscape.