What Makes the Trunnion Ball Valve a Reliable Choice for High-Pressure Industrial Applications?

2025-07-10

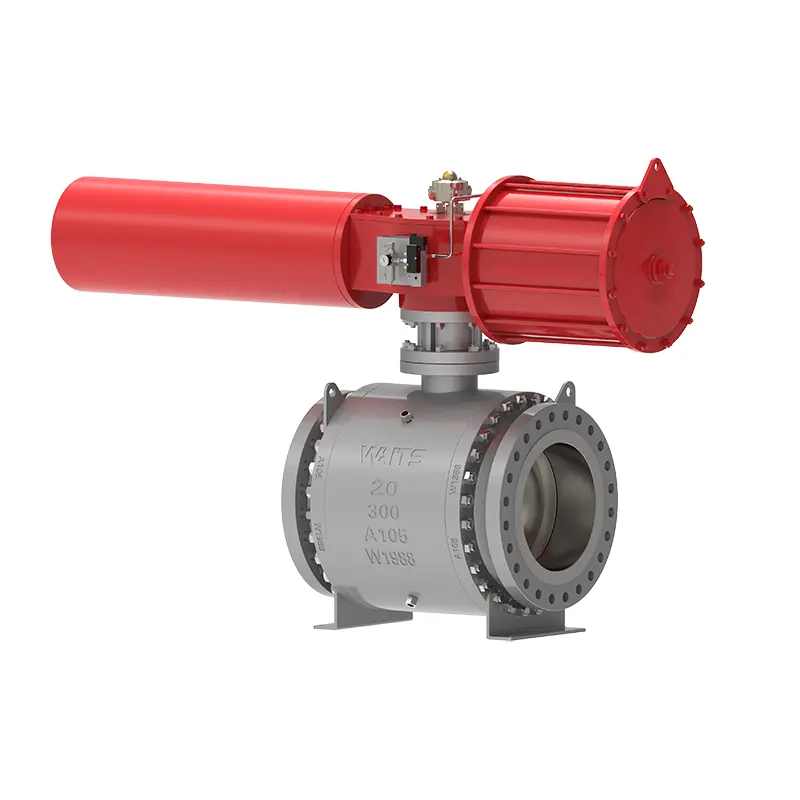

In industrial fluid control systems where reliability, safety, and durability are non-negotiable, our Trunnion Ball Valve stands out as a proven solution. Designed to meet the demands of high-pressure and large-diameter pipeline systems, this valve combines robust engineering with practical safety features to deliver long-lasting and secure performance across a wide range of industries.

Manufactured from forged high-quality steel, the valve body is built for strength and endurance. The trunnion-mounted ball design provides additional stability and reduces operating torque, especially in high-pressure environments. Unlike floating ball valves, where the ball is held in place by the seat rings, the trunnion design anchors the ball at both ends, allowing it to withstand higher pressures with less stress on the seats. This structure also extends service life and improves sealing reliability under demanding conditions.

A key feature of this valve is the flexibility in its sealing system. Depending on the application, users can choose from three types of seat structures: traditional soft seal, triangular ring seal, or hard seal. Each type offers distinct advantages for specific operational environments. For instance, soft seals are ideal for standard conditions with lower temperatures, while hard seals and triangular designs offer superior resistance to high temperatures, corrosive media, and abrasive flow.

The valve from our factory is equipped with upstream and downstream seats that operate with a single-piston effect, allowing for double block and bleed (DBB) functionality. This enhances safety during maintenance by isolating pressure from both sides of the valve. Additional emergency sealing is made possible through strategically placed grease injection ports on both the stem and seat areas. These allow temporary sealing in case of leakage, without interrupting operations—an invaluable feature in critical service environments.

Safety and operational convenience are further addressed with built-in fireproof and anti-static devices, a non-ejectable stem design, and integrated drain and vent valves. The drain valve at the lowest point ensures effective discharge, while the top-mounted vent valve enables safe release of internal pressure or cleaning of the valve cavity during operation. Both components can be configured as isolation valves or specialized discharge fittings to suit various project requirements.

Our Trunnion Ball Valve is also designed for versatile actuation. A universal connection plate allows compatibility with a full range of drive mechanisms, including manual levers, gear operators, electric motors, pneumatic actuators, and electro-hydraulic linkages. This ensures the valve can be easily integrated into automated systems, no matter the scale or complexity.

For buried applications, the valve can be customized with an extended stem and extended piping for grease injection, drainage, and venting—allowing all essential functions to be managed from ground level. The height of these extensions is determined based on specific project needs, ensuring ease of access and maintenance even in below-ground installations.

Available in sizes ranging from 2" to 32" (DN50–DN800) and pressure classes from Class 150 to Class 2500 (PN10–PN420), the Trunnion Ball Valve is a trusted solution for industries such as oil and gas, petrochemical, water treatment, power generation, and more. Its engineered strength, sealing performance, and safety-focused design make it an essential component in any high-pressure pipeline system.